The cosmetic brush printing product logo usually has the following printing methods:

1. Silk printing

Screen printing belongs to stencil printing. The printing plate (the perforations that can pass ink are made on the base of the paper film plate or other plates). When printing, a certain pressure is used to transfer the ink from the perforations of the stencil to the substrate (paper, ceramics, etc.) to form an image Or text. Silk screen printing is not limited by the size and shape of the substrate, and its plate making is convenient and cheap; and the ink layer is thick, the graphic layers are rich, the three-dimensional effect is strong, and the printing material is wide.

Using UV screen ink to print frosting, refraction, ice, wrinkles and other effects on makeup brushes can greatly stimulate consumers’ desire to buy.

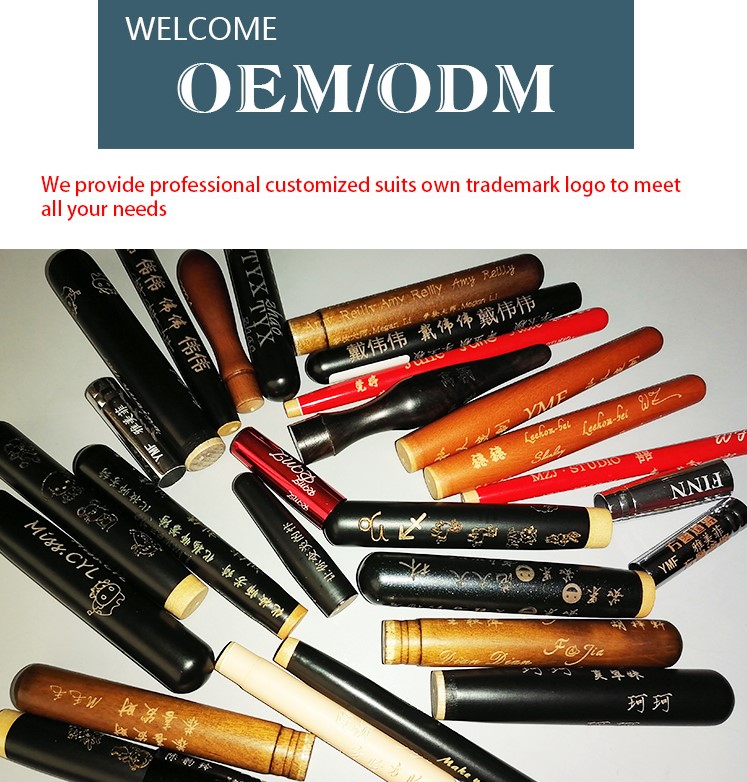

2. Laser carving

Laser carving uses a high-intensity focused laser beam emitted by a laser to oxidize the material and process it at the focal point. It is mainly through the evaporation of the surface material to expose the deep material, or the light energy causes the chemical and physical changes of the surface material to produce traces, or the light energy burns some of the material, and the traces are “carved”, or the light energy burns the part The substance shows the pattern and text to be etched.

3. Hot Stamping

It has the advantages of fine and firm imprinting, good metal texture, strong covering power and high floating power. By heating and pressurizing, the gold foil is imprinted on the paper, which can show a strong metallic luster and lower cost.

The printed patterns are clear, beautiful, colorful, wear-resistant, and weather-resistant. Its effect is remarkable on the trademark and registered name of cosmetics.

4. Roll printing

Roll printing is a cylindrical or cylindrical seal with patterns, patterns and words, or words only.

As a professional makeup brush manufacturer, we can customize printed any logo according to clients’ requirements. Please kindly send us an email for getting more printing information.